A grounding screw, although small in size, plays a key role in ensuring the safety of your electrical system. This irreplaceable component is part of every safely working electrical circuit, providing protection from electrical shock or equipment damage. In essence, the grounding screw forms the grounding pathway, offering a safe alternative conductor for electrical current.

What is a Grounding Screw?

A grounding screw is a fundamental component used in electrical systems to connect the ground wires. Ground wires are an integral component of any electrical scheme, forming an alternative path for electrical energy that may escape the confines of the wires. The screw is typically green and connects the metal portions of a component to the ground wire in the system. It can take several forms, fitting into every kind of modern power device.

Grounding Screw Functionality: Safety First

The function of the grounding screw is not to carry electricity during normal operations. Instead, it provides a "safety net" for any stray electrical current that could potentially harm you or damage your equipment. By providing an alternate path to the ground, a grounding screw helps prevent hazardous situations that could be caused by loose wires or faulty equipment.

Key Functions of a Grounding Screw:

- Reduces the risk of electric shock: Grounding provides an alternate channel for electrical current, precluding the chances of current flowing through a person who may be in contact with a grounding point.

- Stabilizes voltage levels: Grounding plays a crucial role in keeping voltage levels stable. It aids in distributing the correct amount of power to all equipment and promotes better, safer service.

- Prevents damage, fire, or overheating: A grounding system connected with grounding screws protects your devices and your property. It reduces the chances of power surges from harming your appliances or causing fires.

Different Types of Grounding Screws

Various types and sizes of grounding screws are used based on their specific applications. Here are some of the common types:

- Machine Screws: These have machine threads for use with a nut or a tapped hole.

- Self-Tapping Screws: They have a sharp point and are equipped to drill their own hole.

- Hex Head Screws: Recognized by the six-sided head, these screws offer a firm grip.

Installation of Grounding Screws

From electrical boxes to circuit breakers, grounding screws are used everywhere in electrical systems. The process isn't overly complicated but requires care and precision. Here's how you would generally go about it:

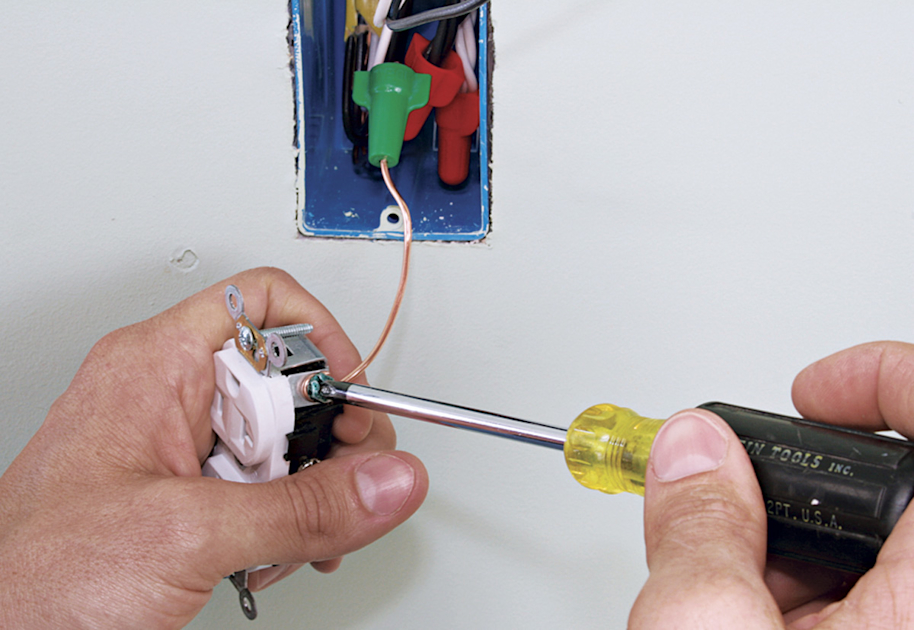

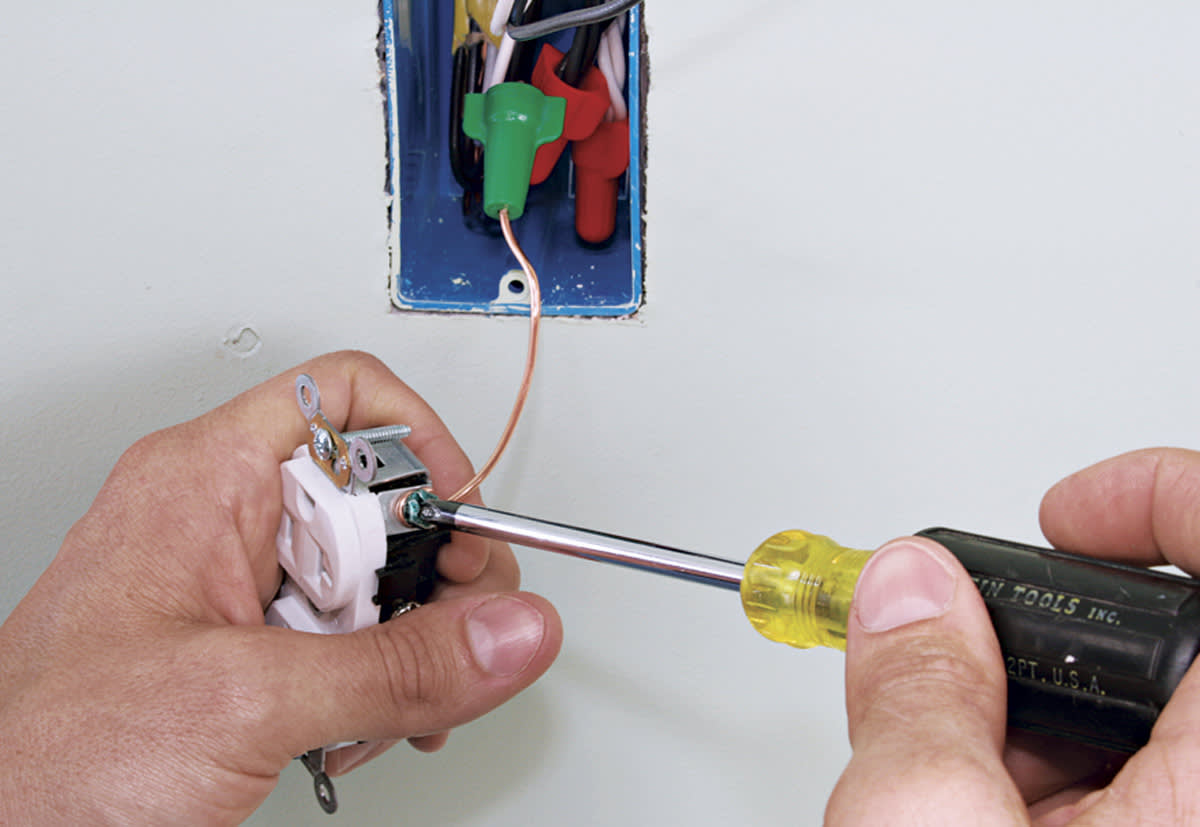

- With the screw held onto the screwdriver's end, insert the screw into the tapped hole on your device.

- Tighten the screw until it is snug, but don't over-tighten.

- Once the screw is tightened, take the ground wire and twist it around the screw. The wire should be wound clockwise along with the direction of screw threading.

- Continue winding until the wire is tightly wound around the screw.

- Use the screwdriver to tighten down the screw, securing the ground wire.

Choosing the Right Grounding Screw

When selecting grounding screws, the most important criteria to consider are the size, type, and material. The right grounding screw for your application should sufficiently conduct electricity and be resistant to corrosion. It should also form the right fit, ensuring a secure grounding connection.

Frequently Asked Questions about Grounding Screw

How Does a Grounding Screw Work?

A grounding screw works by creating a safe path for electrical energy to follow in case there's a fault in the system. The screw typically connects to the metal casing of an electrical device, and a wire then connects from the screw to a grounding source (usually a metal rod driven into the earth).

Where is a Grounding Screw Normally Placed?

The placement of grounding screws can vary depending on the particular installation. However, they're generally screwed into the metal housing of an electrical appliance like a light switch or outlet to ensure a good, conductive connection.

Is a Grounding Screw Necessary in All Electrical Installations?

While grounding screws are not always mandatory in every electrical installation, they add a significant level of safety to them. Including a grounding screw in electrical installations helps to protect one from electrocution by redirecting stray electrical charges safely into the ground.

What Happens if a Grounding Screw is Not Used Correctly?

If a grounding screw is used incorrectly or not used at all when it should be, it can lead to a host of problems. Including the possibility of electric shock or even fire. When a fault occurs, the stray electrical charge may find a path to ground somewhere else, basically anywhere it can. This could mean along the appliance’s casing, leading to significant danger.

Why is a Grounding Screw Usually Green?

Grounding screws are often green to make them easily distinguishable from other screws. The National Electrical Code (NEC) standardises certain colour conventions, green being for grounding screws. This helps maintain consistency and safety across various electrical installations.

Can Grounding Screws be Reused?

While it’s technically possible to reuse grounding screws, it's not always advisable. If the screw shows any signs of wear, stripping or corrosion, it’s best to replace it. They are inexpensive and easy to replace, and doing so can help ensure electrical safety.

What Material is a Grounding Screw Made From?

Grounding screws are typically made of metal that is a good conductor of electricity. Commonly, they are manufactured from brass or steel and are often coated with zinc or covered in a corrosion-resistant finish to enhance longevity.

Pros of Grounding Screws

Safety and Protection

Prevents Electrical Overloads

Grounding screws play a crucial role in our electrical systems by creating a direct pathway for electrical energy to follow should there be any circuit malfunction or overload. By ensuring the excess current safely flows back to the earth, grounding screws drastically reduce the risks of electrical fires, electrocutions, and severe electrical shocks.

Promotes Electrical Stability

Consistent electrical stability is a notable guarantee with grounding screws. They improve the longevity of appliances by stabilizing voltage levels and offering a clear path to the ground. This stability ensures that the right amount of power is supplied to all electrical devices, protecting them from potential harm caused by irregular power surges.

Material and Installation Advantages

Durability

Grounding screws are typically made of strong, corrosion-resistant materials such as zinc-plated steel or brass, offering long-lasting service. These materials offer impressive durability, ensuring the grounding screws can withstand variations in weather conditions and resist both rusting and corrosion, resulting in fewer replacements and lower maintenance costs.

Easy Installation

The simplicity of grounding screw installation adds to their benefits. Unlike some other protective devices, grounding screws do not require any complex or specialized tools during the installation process. With basic knowledge, anyone can easily install a grounding screw in a matter of minutes.

Cons of Grounding Screws

Installation Drawbacks

Improper Installation Risks

The advantages of grounding screws only hold true if they are correctly installed. Incorrect installation can turn an otherwise beneficial device into a potential hazard. For instance, a poorly installed grounding screw might either fail to carry the current back to the ground, cause ground loops, or lead to galvanic corrosion, which could, in turn, lead to severe electrical accidents.

Specific Tools Requirement

Even though grounding screws are relatively easy to install, they still require some specific tools such as a voltage tester, a wire cutter, or a screwdriver. Not all households may have these tools on hand, which could result in additional costs.

Limited Applications

Not Ideal for All Electrical Equipment

Grounding screws are typically fitted in electrical outlets, switch boxes, and light fixtures. Unfortunately, not all electrical equipment supports the use of grounding screws, limiting their protective function. Some appliances or devices may have advanced built-in safety features making grounding screws redundant.

Older Buildings Issue

In older buildings, grounding screws might be difficult to install or might not be installed at all, as older wiring may not support modern grounding techniques. This means that in some situations, upgrading the electrical system would be required before grounding screws can be added, which can be costly and time-consuming.

Physical Drawback

Small Size & Easy to Lose

Grounding screws are usually quite small. While this is not necessarily a disadvantage in terms of their performance, it does mean that they can be easily lost during installation, especially if the person installing them isn't being cautious.

Summary

Well, let's wrap it up, the grounding screw plays a vital role in many wiring systems. This small but sturdy component is critical for both safety and maintaining a smooth operation. We can't neglect it's significance in creating a direct connection to the ground, releasing any undesirable excess electrical energy and ensuring the safety of your appliances and indeed, yourself.

That's the lowdown on grounding screws. They might not always be seen or noticed, but they're a silent hero in protecting our electronics and households. Just imagine - without the safe path to unleash excess electricity provided by grounding screws, we could have serious electrical faults or even dangerous fires on our hands. So, next time you plug in an appliance, spare a thought for the humble grounding screw working behind the scenes.

So, what's the big deal about the grounding screw, you ask? These small pieces of hardware hold a lot of responsibility. Ensuring our safety from electrical hazards and protecting our appliances, grounding screws are a crucial component in any electrical setup. So, even though they might not grab your immediate attention, remember, grounding screws are hard at work, keeping everything grounded and safe.

About Sagan Electric

Sagan Electric, based in sunny Sacramento, CA, is your go-to electric service provider that puts your needs at the forefront. Our tight-knit team of professional electricians is ready round the clock to put their expertise to work in solving your electrical problems. Whether it's a minor repair or a major installation, your trust means the world to us. With strong ties to our Sacramento community, we're more than just your local electric service provider - consider us your friendly neighborhood electricians. So next time when those pesky wiring issues arise, remember - Sagan Electric has got your back!

Tags: electric, installation, hardware,